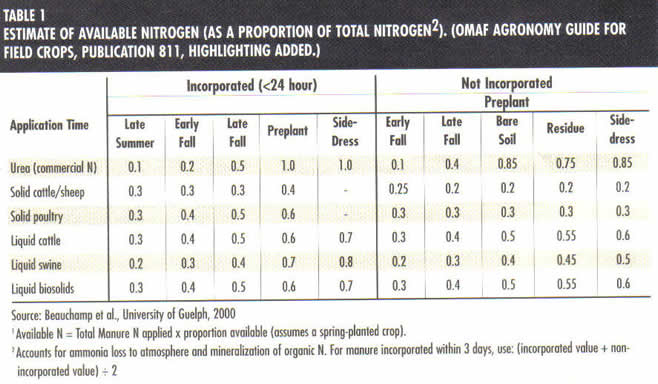

Jake Kraayenbrink of Arthur, Ontario doesn't like the idea of having less than one-half of his hog manure's nitrogen actually be available to the crop when he applies it the previous fall. OMAF recommendations (see Table 1) point out that if he was to sidedress that manure into his standing corn crop, the portion of nitrogen available to the crop would leap to 80%. So that is what he has set out to do.

Krayenbrink's operation uses a Nuhn spreader that has been modified to get down the corn rows and inject the manure into the soil during the sidedress window. The first change to the tanker was to fit it with tandem 18.4 R 38 tires in order to track down the inter-rows without damaging plants. He gets inflation pressures down into the 20-PSI range on these tires. Nuhn Industries reinforced the rims with gussets (see Figure 1) in order to withstand the load of the 4500-gallon spreader. Manure is injected into the inter-rows with a combination of a front coulter and delivery tube mounted on an S-tine.

No Clue Without a Gauge

No Clue Without a Gauge

Yields Keep Climbing

Since converting to sidedress injection of manure several years ago, Jake's continuous corn yields continue to rise. In 2002, he applied 24 Ibs/acre of nitrogen with his dry starter on the planter. All the remaining nitrogen requirements of the corn crop were met with injected manure and his farm average corn yield hovered right around 180 bu/ac. Kraayenbrink acknowledges that it is all not due to sidedress manure injection but he is convinced it is making a big contribution, especially in dry years.Agriculture Canada Research

Scientists Bonnie Ball Coelho and Bob Roy from Agriculture and Agri-Food Canada have also been investigating in-crop manure applications for corn production. In these studies, various rates of liquid hog manure were applied at various timings and using both injection and surface application. This research concluded that injection versus surface application between the corn rows were equally efficient when application was done later in the season (more crop canopy) and in seasons where soil moisture levels were higher. Applying manure early (less crop canopy) and in years where soil conditions were dry, resulted in a large (up to 49 bu/ac) advantage for injection over surface applications.